Why the CircularEconomy Needs Its “Scale”

1. Introduction: Units Alone Are Not Enough

Throughout history, measurement systems have shaped how societies trade, collaborate, and innovate. The introduction of standardized units like the kilogram and the centimeter allowed humans to quantify the world with precision. But these units alone were not sufficient. A kilogram was only useful once a scale existed to measure it. A centimeter only became actionable when paired with a ruler or meterstick. Units required tools of interpretation to become meaningful.

Today, in the context of the circular economy, we find ourselves at a similar moment. We have a unit: the Product Circularity Data Sheet (PCDS)—a standardized digital format to describe the circular characteristics of a product. And we now have a tool: the Circularity Tracker, a system that interprets PCDS data to make it usable and comparable.

=> https://circulartracker.eu/

In this article, we explore the historical development of measurement systems and their tools, and draw a parallel to today’s emerging circular data infrastructure. We argue that while the PCDS is necessary as a unit of circularity, it is not sufficient. To unlock its full value, we need a system like the Circularity Tracker to act as the “scale” of circularity measurement—allowing us to interpret, compare, and act on circularity data at scale.

The PCDS, developed in Luxembourg, is a structured data format that describes a product’s circular profile. It includes indicators such as recycled content, next-use potential, separability, and material recovery. The Circularity Tracker, developed by +ImpaKT, is a digital solution that evaluates and compares these characteristics to support product development, procurement, and regulatory compliance.

2. A World Without Scales or Rulers: Measurement Without Application

Before the adoption of standardized measurement systems, Europe functioned under a confusing and fragmented landscape of local units. Each region had its definitions for length and weight, which made trade difficult, scientific progress unreliable, and taxation inconsistent. The introduction of the meter and the kilogram during the French Revolution represented a radical shift toward universality and scientific reasoning. However, these units only became transformative when paired with tools that allowed people to apply them in practice—namely, the scale and the meterstick.

The scale allowed the kilogram to be used in everyday commerce, ensuring that goods could be weighed fairly and transactions could be trusted across regions. It made taxation more transparent and enabled logistical systems to function with precision. The meterstick brought the concept of the meter into construction, land management, and industrial manufacturing. It enabled the production of interchangeable parts and the consistent measurement of materials, which were critical to the development of mass production and quality control.

Together, these tools turned abstract units into operational systems. They enabled replicable scientific experiments, engineering standards, and national governance mechanisms based on measurable data rather than arbitrary rules. The scale and the meterstick allowed measurements to become the foundation of laws, trade agreements, and technological progress. Their systemic impact was so profound that they helped usher in the modern industrial economy by making consistency, comparability, and trust possible across institutions, borders, and disciplines.

3. The PCDS: A Standard Unit for Circularity

In the modern push for sustainability, the Product Circularity Data Sheet (PCDS) offers a clear parallel to early measurement units. It defines how a product’s circular features are described using a harmonized vocabulary and a machine-readable data structure.

Among the core characteristics covered by the PCDS are recycled content, next-use potential, material recovery potential, and separability—describing the ease with which components or materials can be disassembled without degrading their function. The PCDS also includes transparency of data source, specifying where and how the underlying information was verified.

By enabling these circularity features to be expressed consistently across sectors and supply chains, the PCDS provides a critical foundation for circularity metrics. It supports regulatory alignment with initiatives such as the EU Taxonomy, Digital Product Passport, and ISO 59040. However, just as a centimeter doesn’t measure anything until it is applied with a ruler, the PCDS remains a descriptive format. It tells us what to measure—but not how circular a product is in relation to others.

To visualize this: the PCDS is the ruler, but the Circularity Tracker is the hand that places it along the object, enabling measurement and comparison.

4. The Role of the Circularity Tracker: A System for Evaluation and Comparison

The Circularity Tracker, developed by +ImpaKT, is a digital system that evaluates and compares circularity data drawn from PCDS-compliant formats. After extensive prototyping and testing, the system is now being launched as a practical tool for designers, product managers, procurement officers, and regulators who need to make decisions based on reliable circularity information.

It works by interpreting the PCDS data and applying a scoring logic that allows for benchmarking across products, tracking improvement over time, and aligning performance with sustainability goals or procurement criteria. In doing so, the Circularity Tracker acts as the equivalent of a calibrated scale—transforming the unit into something actionable and comparable.

This system doesn’t replace the PCDS; it completes it. One provides the language. The other provides the logic.

=> https://circulartracker.eu/

4.1 Example: Comparing Two Laptops

Imagine two laptops, both marketed as sustainable. Laptop A is made from 40% recycled plastic, features a modular design, and is easy to repair. Laptop B uses only 10% recycled content, is glued shut, and offers limited repairability. Both manufacturers publish their circularity characteristics using the PCDS.

Using the Circularity Tracker, Laptop A scores significantly higher on material recovery, next-use potential, and separability. Laptop B, while compliant with some basic criteria, falls short in key design-for-circularity indicators. A purchasing team or regulatory body can now compare these two products quantitatively, making informed and transparent decisions possible.

5. Why We Need the Full System: Unit + Instrument

The PCDS and the Circularity Tracker together form a measurement system. One without the other leaves a gap. Circularity data without interpretation is like knowing the length of something but having no way to compare it. Conversely, attempting to evaluate circularity without a standardized unit yields inconsistent and incomparable results—and ultimately, greenwashing.

This system-level view reflects the evolution of sustainability governance. As regulators demand more traceable and auditable ESG data, and as markets begin to price in circularity performance, the need for tools that can convert data into insights becomes urgent.

Just as industrial economies needed weights and measures—and the instruments to use them—the circular economy needs both circularity units and systems to apply them.

5.1 Known Limitations and Considerations

Evaluating circularity is not without complexity. Trade-offs between longevity and material purity, regional variations in end-of-life infrastructure, and data gaps in global supply chains all present real challenges. The Circularity Tracker is not a one-size-fits-all solution but provides a consistent baseline for evaluation.

As the system evolves, further stakeholder input and sector-specific adaptations will be essential. Transparency about assumptions and limitations will remain critical for credibility and uptake.

6. Conclusion: From Concept to Comparison

History shows us that units of measurement become transformative only when paired with tools of interpretation. In the past, a kilogram became useful when we invented the scale. A centimeter changed global construction and engineering when paired with a ruler or meterstick.

Today, the Product Circularity Data Sheet gives us the unit for circularity. But to make it operational—to evaluate, compare, and regulate—we need a system like the Circularity Tracker. With this combination, we can shift from aspiration to application, and from promises to performance.

By building tools that mirror the structure of successful measurement systems of the past, we give the circular economy the infrastructure it needs to scale. Circularity becomes not just a value—it becomes a measurable and comparable dimension of economic activity.

=> https://circulartracker.eu/

Key References (APA Style)

Alder, K. (2002). The Measure of All Things: The Seven-Year Odyssey and Hidden Error That Transformed the World. Free Press.

Heilbron, J. L. (1990). Weighing Imponderables and Other Quantitative Science around 1800. University of California Press.

Quinn, T. (2012). From Artefacts to Atoms: The BIPM and the Search for Ultimate Measurement Standards. Oxford University Press.

Stock, M., Barat, P., de Mirandés, E., & Firlus, M. (2019). The revision of the SI—the result of three decades of progress in metrology. Metrologia, 56(2), 022001. https://doi.org/10.1088/1681-7575/ab0013

Old Version:

From Kilograms to Circularity: Why the PCDS Needs Its “Scale”

1. Introduction: Units Alone Are Not Enough

Throughout history, measurement systems have shaped how societies trade, collaborate, and innovate. The introduction of standardized units like the kilogram and the centimeter allowed humans to quantify the world with precision. But these units alone were not sufficient. A kilogram was only useful once a scale existed to measure it. A centimeter only became actionable when paired with a ruler or meterstick. Units required tools of interpretation to become meaningful.

Today, in the context of the circular economy, we face a parallel challenge. We have a standardized “unit” for circularity: the Product Circularity Data Sheet (PCDS), a structured digital format designed to describe a product’s circular characteristics. However, to truly measure product circularity and translate this data into actionable strategies, a complementary system is essential. This is where the Circularity Tracker enters the equation – a robust circularity measurement system that operationalizes PCDS data, transforming it into transparent, comparable insights.

While the PCDS is indispensable as a common language of circularity, it is not sufficient on its own. To unlock its full potential, organizations need a system like the Circularity Tracker, effectively the “scale” for circularity, enabling them to interpret, benchmark, and act decisively on circularity data.

The PCDS, developed in Luxembourg, is a structured data format that describes a product’s circular profile. It includes indicators such as recycled content, next-use potential, separability, and material recovery. [1] The Circularity Tracker, developed by +ImpaKT, serves as a circularity data interpretation tool, evaluating and comparing these characteristics to support circular design, sustainable procurement, and regulatory compliance in line with emerging circular procurement criteria.

2. A World Without Scales or Rulers: Measurement Without Application

Before standardized measurement systems, Europe operated under a fragmented landscape of local units for length and weight. Each region had its own definitions for length and weight, which made trade difficult, scientific progress unreliable, and taxation inconsistent. The introduction of the meter and kilogram during the French Revolution marked a pivotal move toward universal, comparable standards. However, these units only became transformative when coupled with practical tools. Namely, the scale and the meterstick that enabled reliable application and benchmarking.

The scale allowed the kilogram to be used in everyday commerce, ensuring that goods could be weighed fairly and transactions could be trusted across regions. It made taxation more transparent and enabled logistical systems to function with precision. The meterstick brought the concept of the meter into construction, land management, and industrial manufacturing. It enabled the production of interchangeable parts and the consistent measurement of materials, which were critical to the development of mass production and quality control. Moreover, these early tools for benchmarking allowed societies to build reliable systems based on measurable data instead of subjective judgment.

Together, these tools turned abstract units into operational systems. They enabled replicable scientific experiments, engineering standards, and national governance mechanisms based on measurable data rather than arbitrary rules. The scale and the meterstick allowed measurements to become the foundation of laws, trade agreements, and technological progress. Their systemic impact was so profound that they helped usher in the modern industrial economy by making consistency, comparability, and trust possible across institutions, borders, and disciplines

This historical evolution mirrors today’s challenge of how to measure product circularity. While the Product Circularity Data Sheet (PCDS) provides a standardized digital unit to describe a product’s circular attributes, it requires operational tools to unlock its value. The Circularity Tracker acts as a modern “scale”, transforming PCDS data into actionable insights that enable transparent circularity measurement systems, support compliance with circular procurement criteria, and allow organizations to benchmark circular performance reliably.

The combination of the PCDS and the Circularity Tracker enables organizations to compare, interpret, and act on circularity data, establishing a foundation for future-ready supply chains, product development, and sustainable business strategies. This integrated approach makes circularity measurable, comparable, and actionable, ultimately accelerating the global transition toward a regenerative economy.

3. The PCDS: A Standard Unit for Circularity

In the drive toward sustainable business models, the Product Circularity Data Sheet (PCDS) serves as a standardized unit for describing product circularity. Much like the early adoption of universal measurement units, the PCDS establishes a harmonized vocabulary and a machine-readable data structure that allows organizations to communicate circular attributes clearly and consistently.

Among the core characteristics covered by the PCDS are recycled content, next-use potential, material recovery potential, and separability, describing the ease with which components or materials can be disassembled without degrading their function. The PCDS also includes transparency of data source, specifying where and how the underlying information was verified.

By enabling these circularity features to be expressed consistently across sectors and supply chains, the PCDS provides a critical foundation for circularity metrics. It supports regulatory alignment with initiatives such as the EU Taxonomy, Digital Product Passport, and ISO 59040. However, while the PCDS tells us how to measure product circularity in theory, it does not provide actionable insight on its own. The PCDS defines what should be measured, but not how to interpret or benchmark it in a comparative, operational context. Without advanced circularity data interpretation tools, the PCDS remains a static format, similar to a ruler without a guiding hand.

Here, the Circularity Tracker becomes essential. It functions as the practical application tool that interprets PCDS data, transforming static information into meaningful, comparable metrics. The Tracker acts as a dynamic engine for tools for circularity benchmarking, enabling businesses to evaluate products side by side, identify improvement opportunities, and support strategic decisions. In this integrated system, the PCDS provides the “unit,” and the Circularity Tracker provides the “measurement”

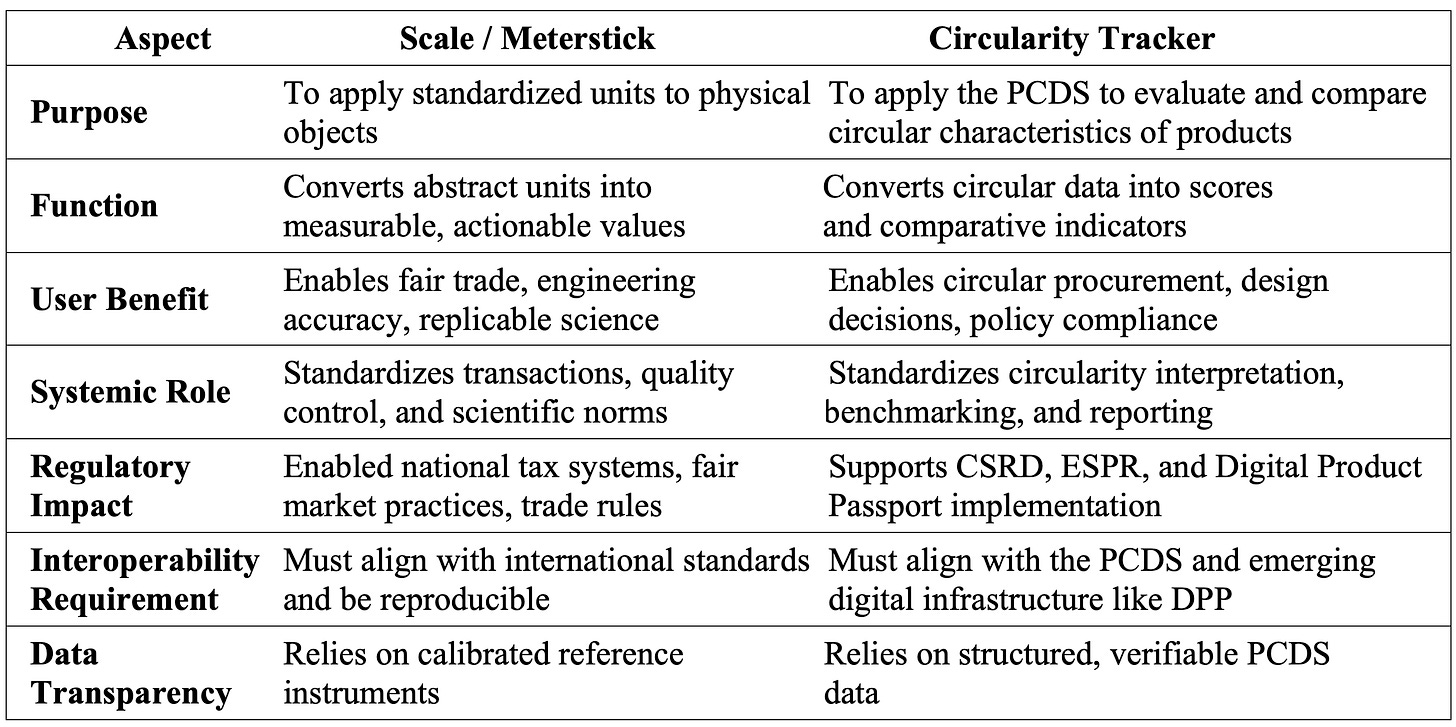

To visualize this:

| Aspect Scale / Meterstick Circularity Tracker |

| Purpose To apply standardized units (kg, cm) to physical objects To apply the PCDS to evaluate and compare circular characteristics of products |

| Function Converts abstract units into measurable, actionable values Converts circular data into scores and comparative indicators |

| User Benefit Enables fair trade, engineering accuracy, replicable science Enables circular procurement, design decisions, policy compliance |

| Systemic Role Standardizes transactions, quality control, and scientific norms Standardizes circularity interpretation, benchmarking, and reporting |

| Regulatory Impact Enabled national tax systems, fair market practices, trade rules Supports CSRD, ESPR, and Digital Product Passport implementation |

| Interoperability Requirement Must align with international standards and be reproducible Must align with the PCDS and emerging digital infrastructure like DPP |

| Data Transparency Relies on calibrated reference instruments Relies on structured, verifiable PCDS data |

4. The Role of the Circularity Tracker: A System for Evaluation and Comparison

The Circularity Tracker, developed by +ImpaKT, is a digital system that evaluates and compares circularity data drawn from PCDS-compliant formats. After extensive prototyping and testing, the system is now being launched as a practical tool for designers, product managers, procurement officers, and regulators who need to make decisions based on reliable circularity information.

It works by interpreting the PCDS data and applying a scoring logic that allows for benchmarking across products, tracking improvement over time, and aligning performance with sustainability goals or procurement criteria.

By leveraging the structured data within the PCDS, the Circularity Tracker applies a sophisticated scoring framework that enables tools for circularity benchmarking. It allows organizations to benchmark products against one another, monitor progress over time, and align performance with sustainability targets and circular criteria. In this role, the Circularity Tracker functions as a calibrated scale, transforming descriptive data into quantifiable, comparable results. Crucially, the system does not replace the PCDS; it operationalizes it.

The PCDS offers the standardized “language” of how to measure product circularity, while the Circularity Tracker provides the analytical “logic”, the interpretative layer that enables organizations to act strategically on circularity data at scale. This powerful combination accelerates the transition toward a more circular economy by making data-driven decision-making both practical and measurable.

4.1 Example: Comparing Two Laptops

Imagine two laptops, both marketed as sustainable. Laptop A contains 40% recycled plastic, has a modular design, and is easy to repair. Laptop B uses only 10% recycled content, is glued shut, and offers limited repairability. Both manufacturers publish their circularity characteristics using the PCDS.

Using the Circularity Tracker, Laptop A scores significantly higher on material recovery, next-use potential, and separability. Laptop B, while compliant with some basic criteria, falls short in key design-for-circularity indicators.

A purchasing team or regulatory body can now compare these two products quantitatively, supporting informed and transparent decisions.

5. Why We Need the Full System: Unit + Instrument

The Product Circularity Data Sheet (PCDS) and the Circularity Tracker together establish a robust circularity measurement system. Without the synergy between a standardized data unit and an interpretation tool, the value chain remains fragmented. Circularity data without a dynamic circularity data interpretation tool is like knowing a length but lacking a ruler to benchmark it. Conversely, assessing circularity without a harmonized data format leads to inconsistent, non-comparable results, ultimately fueling greenwashing risks.

This system-level view reflects how sustainability governance is evolving. As regulators demand more traceable, auditable ESG data, and as markets begin to price in circularity performance, the need for tools that can convert data into insight becomes urgent.

Just as industrial economies needed weights and measures, and the instruments to use them, the circular economy needs both circularity units and systems to apply them.

5.1 Known Limitations and Considerations

Evaluating circularity is not without complexity. Trade-offs between longevity and material purity, regional variations in end-of-life infrastructure, and data gaps in global supply chains all present real challenges. The Circularity Tracker is not a one-size-fits-all circularity measurement system, but it offers a consistent, standardized baseline for circularity benchmarking across industries.

As the system evolves, further stakeholder input and sector-specific adaptations will be essential. Transparency about assumptions and limitations will remain critical for credibility and uptake.

6. Conclusion: From Concept to Comparison

History shows us that units of measurement become transformative only when paired with tools of interpretation. In the past, a kilogram became useful when we invented the scale. A centimeter changed global construction and engineering when paired with a ruler or meterstick.

Today, the Product Circularity Data Sheet gives us the unit for circularity.

But to make it useful to evaluate, compare, and regulate, we need a system like the Circularity Tracker. With this combination, we can shift from aspiration to application, and from promises to performance.

By building tools that mirror the structure of successful measurement systems of the past, we give the circular economy the infrastructure it needs to scale. Circularity becomes not just a value. It becomes a measurable and comparable dimension of economic activity.

0 Comments