Circularity doesn’t need more pilot projects or glossy visions. It needs connective tissue.

Imagine a world where circular products data move through the economy as seamlessly as shipping containers move through global ports. We’re not there yet—but we could be.

In today’s push for a circular economy, standardization is often overlooked—but it is one of the most powerful tools to drive efficiency, scale, and sustainability. A perfect historical case study? The humble shipping container. Tools like the Product Circularity Data Sheet (PCDS) could become the shipping containers of the circular economy.

The Chaos Before Standardization

Before the 1950s, global trade was painfully slow. Ports were clogged with workers manually loading and unloading cargo—each shipment a jigsaw puzzle of crates, barrels, and bags of all sizes. It took days to process a single ship, and the costs were astronomical:

- $5.86 per ton to load/unload a ship

- Ships were only 35% full on average due to inefficiencies

- Theft, damage, and labor disputes were rampant

The system was inefficient, costly, and unreliable. Trade was limited to those who could afford the complexity.

The Standardization Revolution

Enter Malcolm McLean, a trucking entrepreneur with a radical idea: what if goods were packed into uniform, stackable metal boxes that could move seamlessly between trucks, trains, and ships? In 1956, he launched the first containerized ship, cutting port costs and reducing handling time by over 84%. The results were undeniable.

But here’s the key: it wasn’t just the invention of the container—it was the standardization of the system that made it revolutionary.

By the late 1960s, the International Organization for Standardization (ISO) had established global specifications for container dimensions and locking mechanisms. Suddenly, ports, ships, and logistics companies around the world were speaking the same “language.” This shift unlocked unprecedented efficiency, scale, and economic growth.

The Economic Impact of Standardization

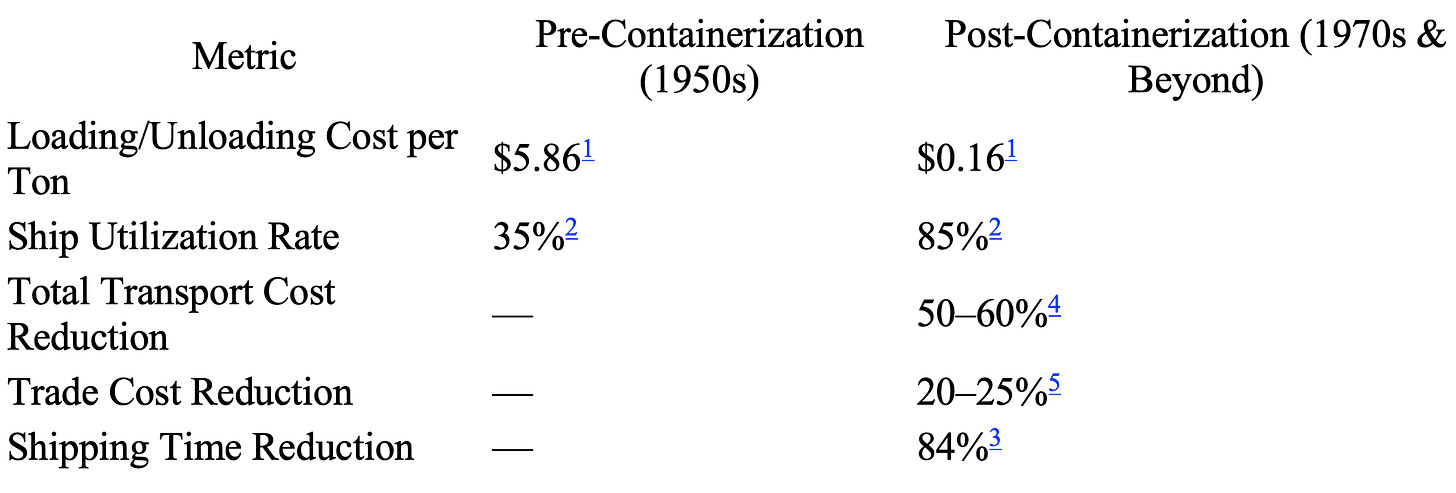

Standardization didn’t just make things simpler—it made them cheaper, faster, and scalable:

How the Container Transformed Infrastructure and Logistics Operations

The shipping container didn’t just revolutionize trade—it reshaped the entire infrastructure of global logistics.

Before standardization, ports were chaotic spaces built around manual labor and bulk storage. Goods had to be repackaged multiple times as they moved from ship to train or truck. Warehouses dominated port areas, and every port required custom handling systems.

The container changed all of that:

- Ports became container terminals – Entire harbors were redesigned around cranes, not dockworkers. Ports like Rotterdam and Singapore became global leaders by adapting early.

- Warehouses gave way to open-air storage – Sealed, stackable containers eliminated the need for indoor warehousing, drastically reducing infrastructure costs.

- Automation became viable – Standard sizes allowed for cranes, conveyors, and software to automate logistics with precision. Containerization triggered the era of digitized, high-throughput logistics.

This transformation demonstrates how infrastructure evolves with system-level standardization—a critical insight for the circular economy.

Lessons for the Circular Economy

What does all this mean for circularity? Simple: standardization enables scale.

- Interoperability – When supply chain actors use standard formats and definitions, processes become more efficient. Imagine standardized formats for reusable components or circularity metrics.

- Scalability – Just like containers unlocked global trade, standardizing data, materials, and protocols can take circular business models from pilot to mainstream.

- Innovation & Investment – Clear frameworks allow companies to invest with confidence. Fragmentation kills momentum; alignment accelerates it.

- Cost & Efficiency – Standardized reverse logistics, reuse systems, and material passports reduce transaction costs and complexity—making circular options financially viable.

Real-World Examples of Circular Standards

The good news? Standardization in the circular economy is already underway:

- Product Circularity Data Sheet (PCDS) ISO 59040 – Developed in Luxembourg, this tool provides a standardized digital format to share circular information about products. It helps buyers, engineers, and regulators describe circular product performance.

- ISO 59000 series – These international standards formalize the structure, definition, and governance of circular economy principles and data across sectors, building a global language for circularity.

These efforts are not theoretical. They are the first bricks of a standardized circular economy infrastructure, just as ISO containers once were for global trade.

Who Should Drive Circular Standardization?

In sectors like construction, a clear roadmap is emerging:

- Building owners must demand better product and material data to support reuse, design for disassembly, and optimized maintenance.

- Architects and designers need access to circular data early in the design process to select the right solutions and plan for adaptability.

- Suppliers and manufacturers can leverage tools like the PCDS to demonstrate how their products outperform linear alternatives—turning transparency into a competitive edge.

It is essential to note that in Luxembourg, some institutional actors are starting to request PCDS data.

Collaboration across the value chain is key. Without shared goals and aligned data formats, circularity remains fragmented.

Standardization Alone Won’t Solve Everything—But It’s the Foundation

Standardization won’t eliminate every barrier. Conflicting regulations, data ownership concerns, and the need for contextual flexibility are real. But as the shipping container showed, systemic alignment doesn’t require perfection—it requires commitment.

Just like ports and logistics evolved around a shared system, circular economy infrastructures—from digital product passports to refurbishment networks—can flourish when the foundation is aligned.

Take the First Step Toward Alignment

- If you’re a building owner, ask for circular product data from your suppliers using the PCDS.

- If you’re a policymaker, push for its integration in procurement frameworks and Digital Product Passport discussions.

- If you’re a manufacturer, use it to prove how your products outperform linear alternatives—on real circular metrics.

- If you’re a designer or architect, demand access to standardized circularity info at the start of your design process.

Standardization isn’t bureaucracy—it’s the prerequisite for scale.

Final Thought

Despite all the circular economy headlines, most companies still rely on Excel files, unstructured PDFs, and vague product claims. The result? A fragmented, friction-filled system that kills scale and rewards circular washing over transparency.

The shipping container didn’t change the world because it was a metal box—it changed the world because it was a standardized system that made global trade efficient and scalable.

Circularity doesn’t need more pilot projects or glossy visions. It needs connective tissue.

The path forward? Don’t just innovate the product—standardize the system.

What’s the “shipping container moment” for the circular economy? It’s the moment we stop improvising and start aligning. It’s the moment we agree on data formats, reporting rules, and performance metrics that let real business models emerge.

The Product Circularity Data Sheet (PCDS) might just be that moment—a standard unit for describing product circularity, recently formalized as ISO 59040. Like the 1kg weight or the ISO container, it gives everyone the same starting point.

Let’s use it together.

Circularity will not scale through inspiration alone. It will scale through structure.

What would a “container moment” look like in your industry?

Hit reply, share your thoughts, or forward this to someone who’s still waiting for alignment.

👉 If you want more information about the Product Circularity Data Sheet (PCDS) and ISO 59040, reach out to us via the contact form at https://positiveimpakt.eu

📚 References

- Levinson, M. (2006). The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger. Princeton University Press.

- Rodrigue, J.-P., Comtois, C., & Slack, B. (2017). The Geography of Transport Systems. Routledge.

- UNCTAD (2007). Review of Maritime Transport 2007. United Nations Conference on Trade and Development.

- Hummels, D. (2007). Transportation Costs and International Trade in the Second Era of Globalization. Journal of Economic Perspectives, 21(3), 131–154.

- World Bank (2009). Doing Business in a More Transparent World. World Bank Group.

About the author

Jeannot Schroeder is founder of +ImpaKT and co-developer of the Product Circularity Data Sheet (PCDS), recently standardized as ISO 59040. He advises governments and companies on how to scale circularity through data, strategy, and system thinking.

0 Kommentare